Strain Gages

- Although there are many machineries and struactures in which we are now living for carrying out a modern social operation, we will not be able to keep a life smoothly and safely unless functions or safety of these facilities be fully ascertained. Strain gages have developed and widened the scope of their application as one of the most fundamental means to confirm the degree of safety of machinery and structures we are using and also as the sensors to actually detect and measure strains and stress at the spot.The history of these strain gages is considerably long and old and the bonded type strain gages which we are currently using have been designed and schemed initially in 1938 by Simmons & Ruge in America. Our SHOWA Company started manufacture of strain gages for the first place in Japan in 1962 as the foil grid type strain gages. Strain gages are really indispensable means to detect strength and properties of metals, rubber, plastics, ceramics which we are using in our daily life.

-

Strain gage construction, specifications and type indication

Standard strain gage types and basic patterns

Standard strain gauges used for stress measurement

| Kinds | Uniaxial Strain Gages | Biaixal Strain Gages | Triaxial Strain Gages | Stress Concentration Measurements |

|---|---|---|---|---|

| Pattern Code | N11… | N22… | N32… | R11,N51,R51… |

| Lead wire pre-attached | N11…VS… | N22…VS… | N32…VS… | R11,N51,R51…VS… |

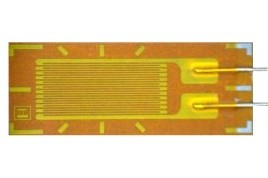

| Basic pattern |  |

|

|

|

These are strain gages complying with the aim of measurements of shearing stress and relating torque and measurements of axial power by means of pipe type strain gages.

| Kinds | Uniaxial 45° | Crack Detection | Pipe Gage |

|---|---|---|---|

| Purpose | Shearing stress and torque measurement | Crack propagation detection and analysis | Bolt spindle power measurement-Click- |

| Pattern Code | Z11… | X11… | P11… |

| Basic pattern |  |

|

|

- Strain gages with polyester coated lead wires (Lead wire: “L”).

- Strain gages with teflon coated lead wires for high temperature applications (Lead wire: “FE”).

- Strain gages with supporting base cut treatment (Base Trim: “A”)

- Strain gages with provision of tabs (Tabs are provided at both sides of strain gage grid.) Applicable strain gage types: T11, T24, U11…

- Rosette patttern strain gages, Non-intersectional triaxis type, delta type, Y-shaped type, and so on. Applicable strain gage types: N21, N31, N34, N35 …

Strain gage terminals

Adhesives for strain gages

Humidity-proof coating materials for strain gages

Tech Information / What is strain gage measuring ?

- Measurements by means of strain gages are in the world of 1/1,000,000…

- Purpose of measurements by means of strain gages…

- Terminology and expressions wothy to know of in relation with strain gages…

- Self temperature compensation strain gages…

- Thermal characteristics of strain gages…

- Stress-strain curves…

- Simple method for generating equivalent strain by inserting a parallel resistor into one side of the strain gage bridge…

- Calculation of tension and compression stress…

- Calculation of bending stress…

- Calculation of shearing stress..

- Calculation of torsional stress…