Load Cells

- There are several detection systems in the force detection devices, such as strain gage type, piezzo-electric type, capacitance type, electro-magnetic type, tuning fork type, and so on, among which the strain gage type detection system is so widely diffused in this field that this type of detection system is commonly called as load cells. The load cell has in it an elastic body called strain transmitting element on which strain gages are bonded. Its principle of measurement is to utilize the proportional relation between the stress (force) applied and the strain generated. The devices having such a wide measuring range from the low class capacity of 200mN to the high class capacity of 20MN can be produced and offered. Its customary fields of application have been only for the limited production lines in the materials testing machines, industrial measuring and testing machines, (including batchers, hoppers, truck scales, etc.), steel rolling mills and so on. But as the superiority in performances, cost-effectiveness and reliability of load cells have become aware among users, the load cells are at present widely utilized in high accuracy platform scales, electronic balances and so on and also for the quality control of public equipment or devices. In the course of elevation in recent days of the demands or requirements for the engineering plastic equipment, the use of electro motive servo device incorporating load cells therein has occupied a main role in the jet moulding systems for the realization of accurate high speed stable moulding in clean atmosphere.

-

Showa Sokki load cell types

- Click individual “TYPES” for respective appearances or specifications.

- The rating steps of respective TYPES are fundamentally to be 1, 2, 5, 10 …. / the respective units.

- Rated capacities are all indicated in the SI unit, namely, the customary unit / the converted SI Unit: 1kgf = 9.80665N.

- For load cells for load testers compatible with JCSS calibration, see here.

- Click here in regard to Load Cells accessories.

Tension & Compression Load Cells

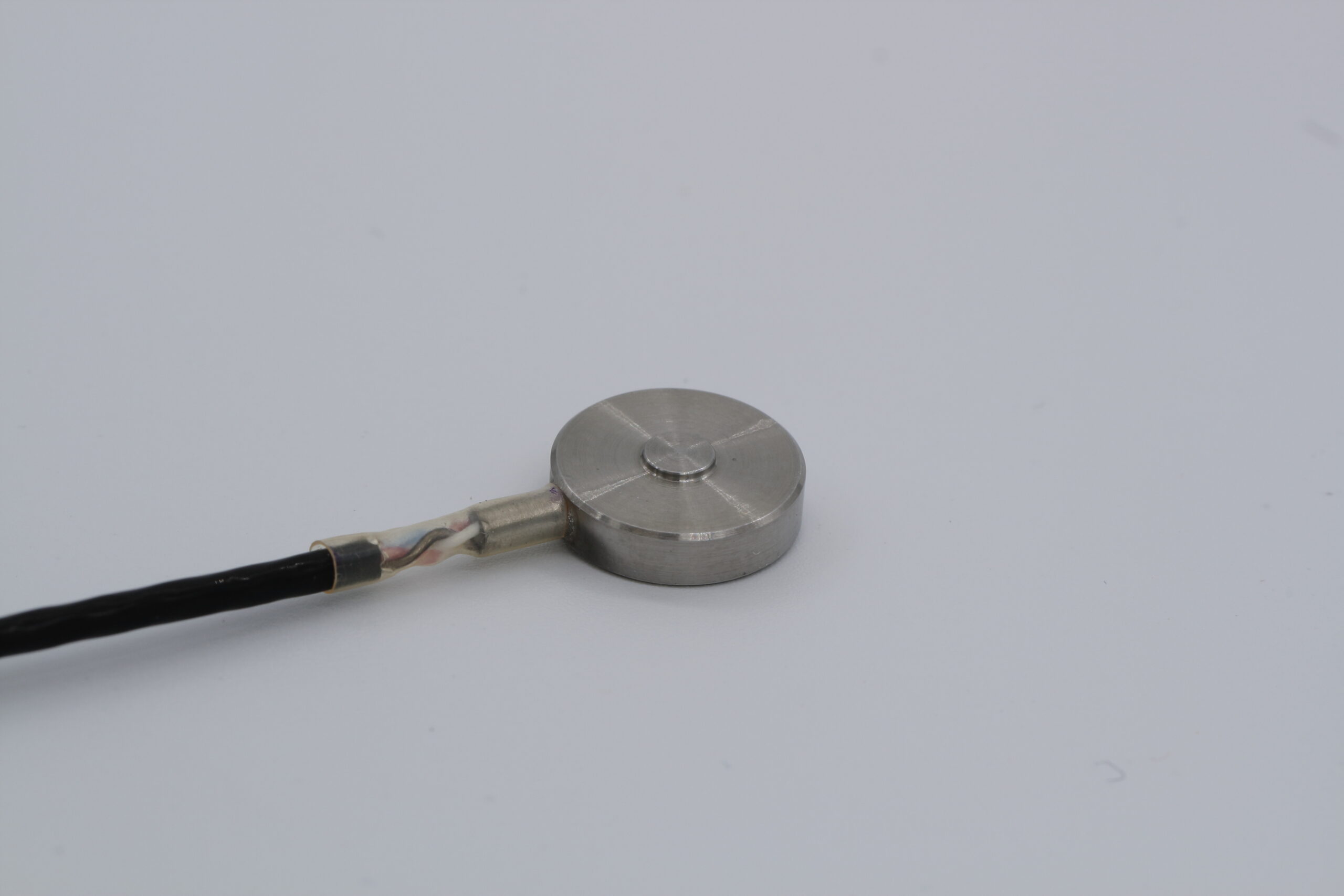

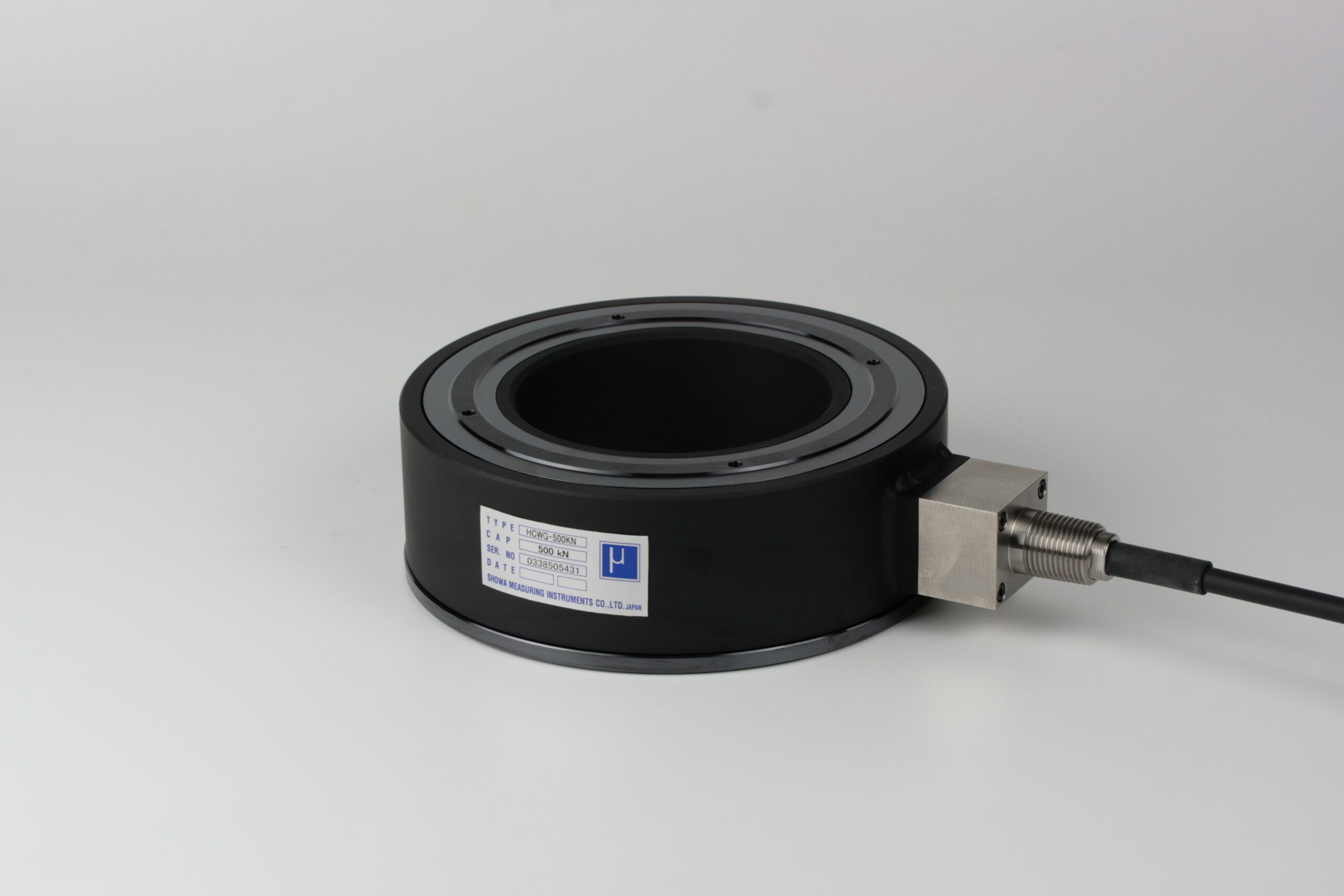

Compression Load Cells

Tension Load Cells

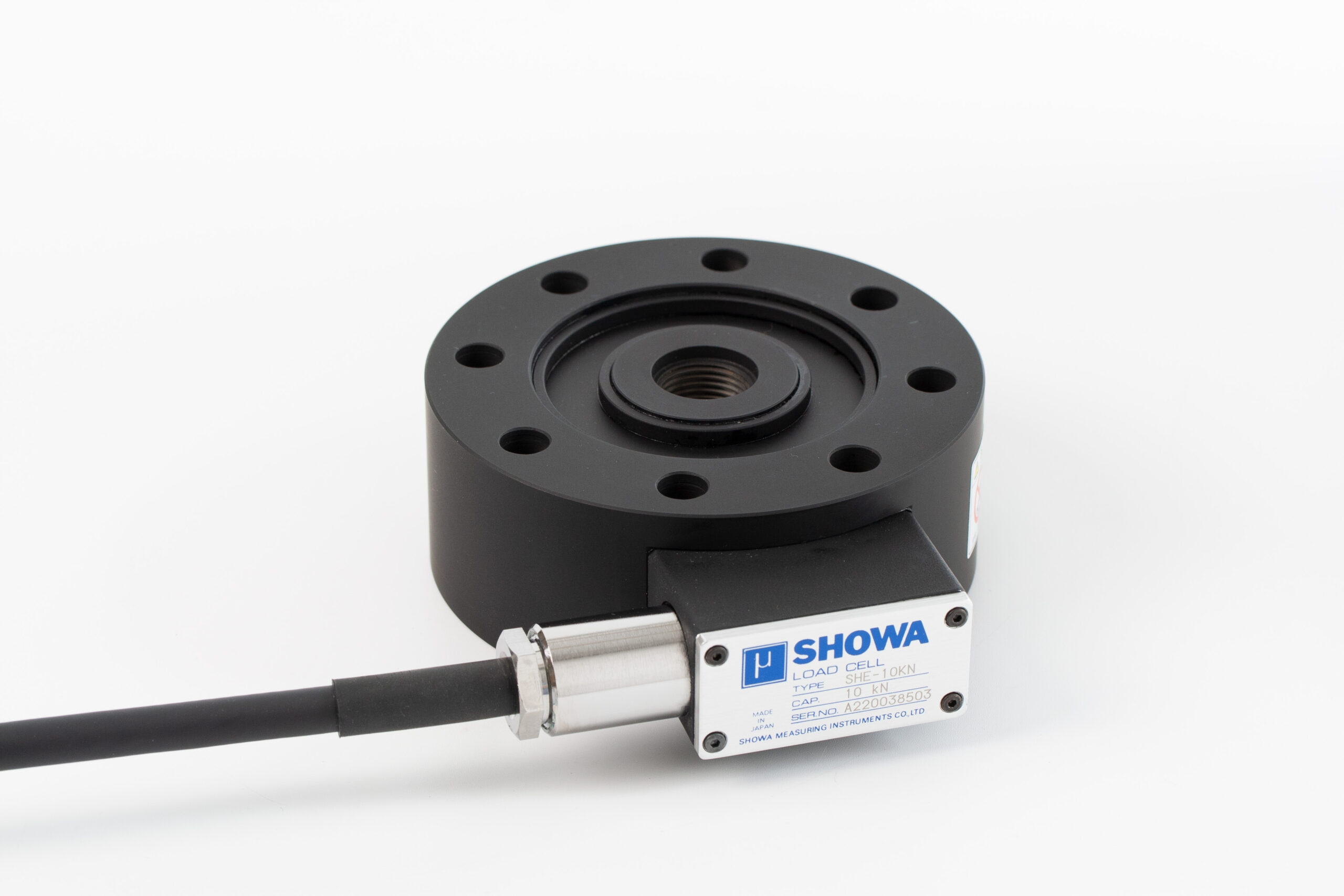

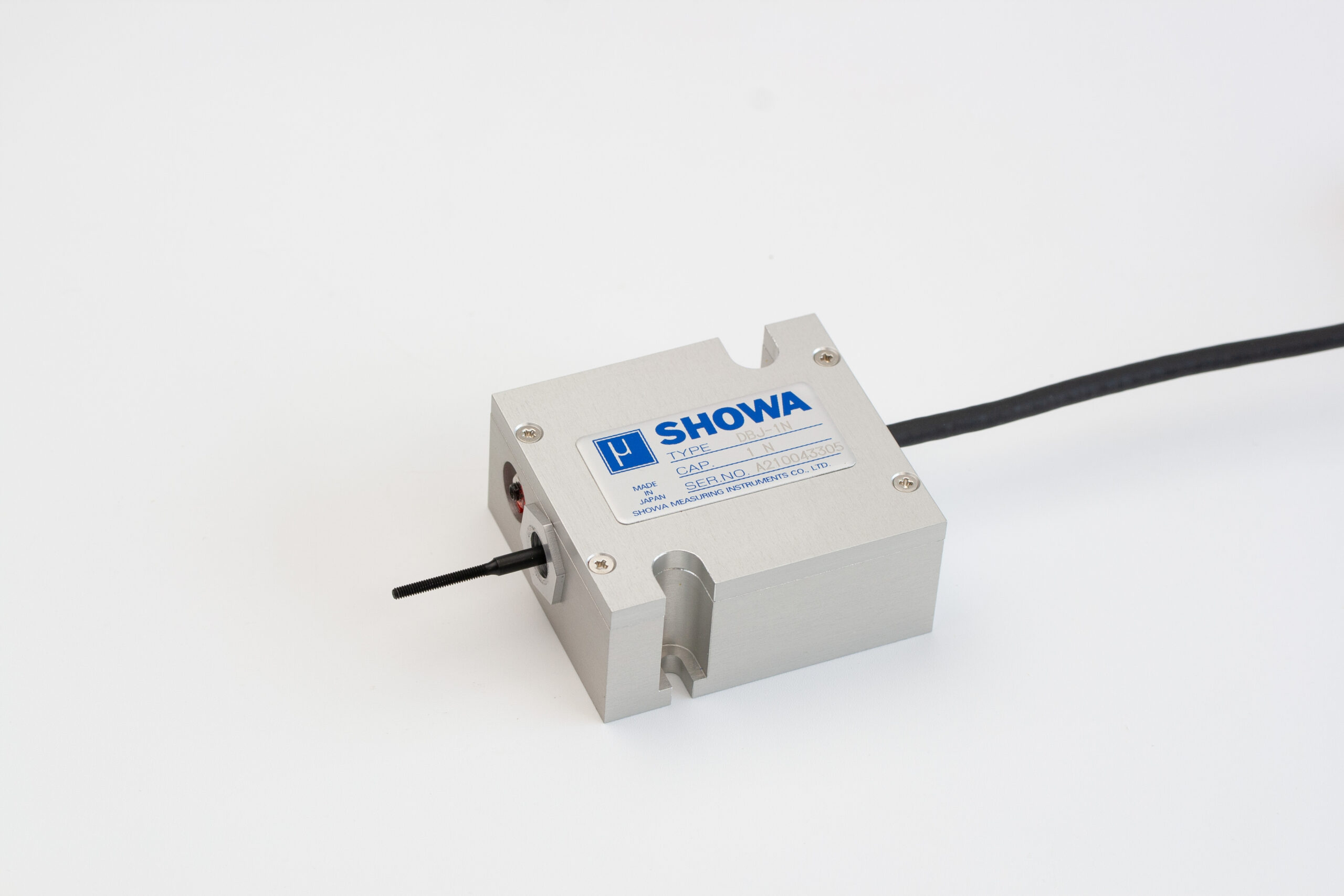

| Product image | Type | Structure and features | Rated range | linearity(%RO) | Rated output(mV/V) | Operating temperature(℃) |

|---|---|---|---|---|---|---|

|

RTD | Coaxial beam type,General Purpose | 500 N,..20 kN | 0.15 | 2.0±1 % | -10~60 |

|

RTD-UA | Coaxial beam type,Water Proof,General Purpose | 500 N,..20 kN | 0.15 | 2.0±1 % | -10~60 |

|

RTB | Coaxial beam type,Attached Rod-end,General Purpose | 50 N,..5 kN | 0.15 | 1.5±1 % | -10~60 |

|

MRDT-C | Ultra-small type,General Purpose | 50 N,..2 kN | 0.5 | 1.0±20 % | 0~60 |

|

DB | Coaxial beam type,High Accuracy,General Purpose | 200 N,..20 kN | 0.02 | 3.0±1 % | -10~60 |

|

DBS | Coaxial beam type,High Accuracy,Low Cost,General Purpose | 200 N,..50 kN | 0.05 | 3.0±1 % | -10~60 |

JCSS-calibration-compliant Load cells for force testers

| Product image | Type | Structure and features | Rated range | linearity(%RO) | Rated output(mV/V) | Operating temperature(℃) |

|---|---|---|---|---|---|---|

|

RCF | For compression Force gauge*1 | 500 N,..10 MN | 0.05 | 2.0±1 % | 0~40 |

|

RTU-S2B | Tensile force gauge*1 | 50 N,..200 kN | 0.03 | 2.0±1 % | 0~40 |

|

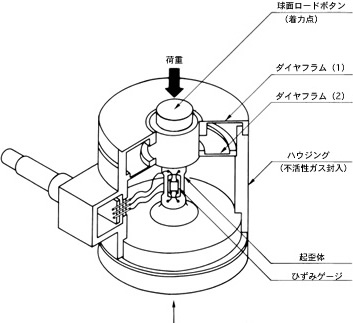

CHM | For hardness tester verification*1 | 1 N,..2 kN | 0.05 | 1.5±1 % | -10~60 |